Welcome

Control System Services was born from the need for a control systems integrator that understands the technologies of yesterday and today! Not every organization can upgrade their legacy control system to keep up with the latest trends. It's working, why "fix" it? Sometimes your budget just doesn't allow for an upgrade of that financial magnitude. However, those systems cannot be ignored. Over time, the importance of updating grows exponentially. Supply chain issues are putting us all in a very unique situation. It's not if, but when your system fails, what happens if you cannot find replacement parts to get you back up and running in a timely manner? Can you wait a month or two to find replacements? At CSS, we have decades of experience installing and maintaining those older control systems, as well as the expertise to install the latest and greatest controls. If you need help maintaining your current control system without breaking the bank, give us a call for a no obligation assessment. Let us put our 30+ years of industry expertise to work for you. If you are ready to make the move to a new control system, we can help with that as well. We can upgrade that old system to help increase productivity and efficiency. A little at a time, to ease the pain of a large investment, or all at once.

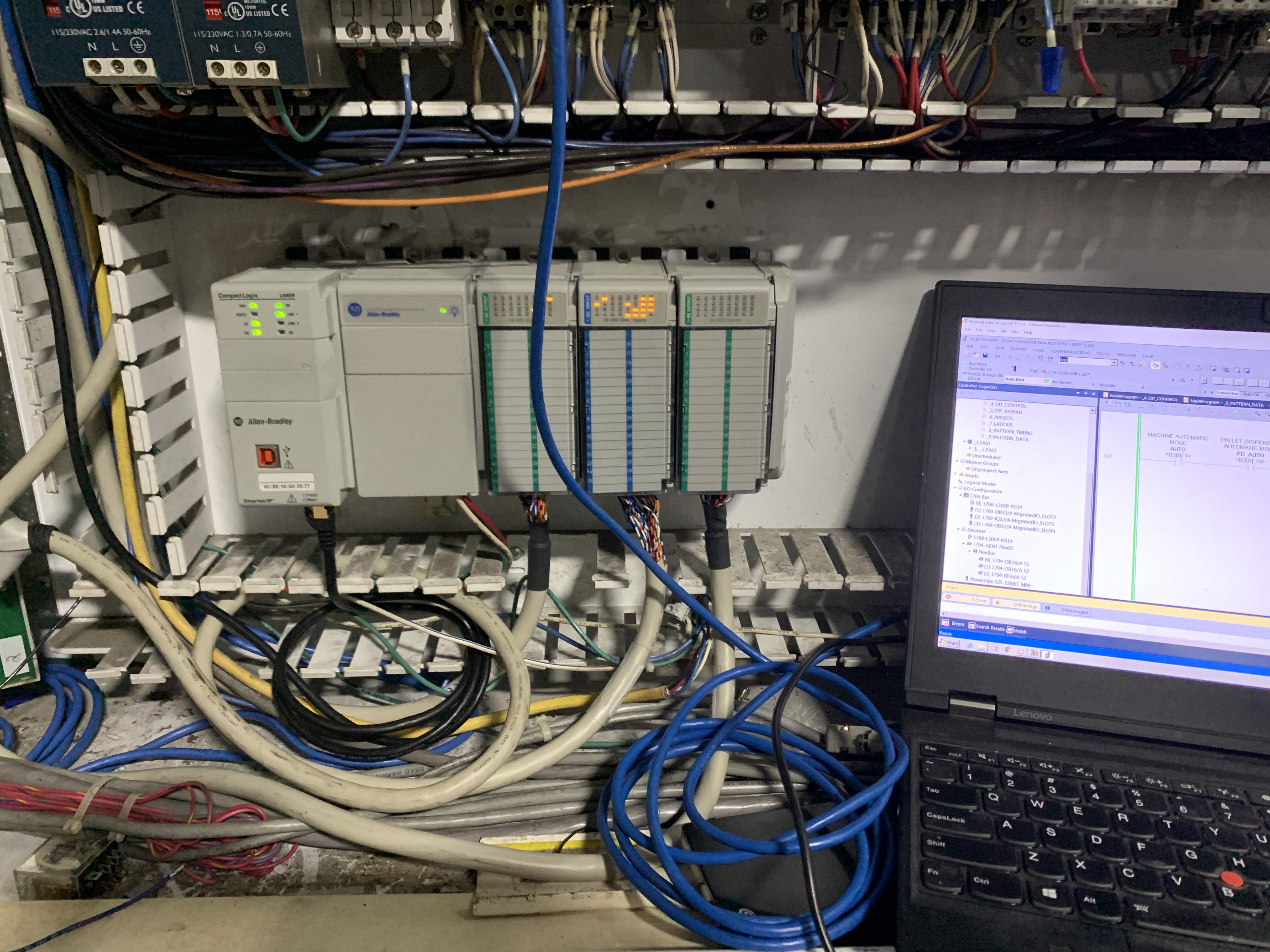

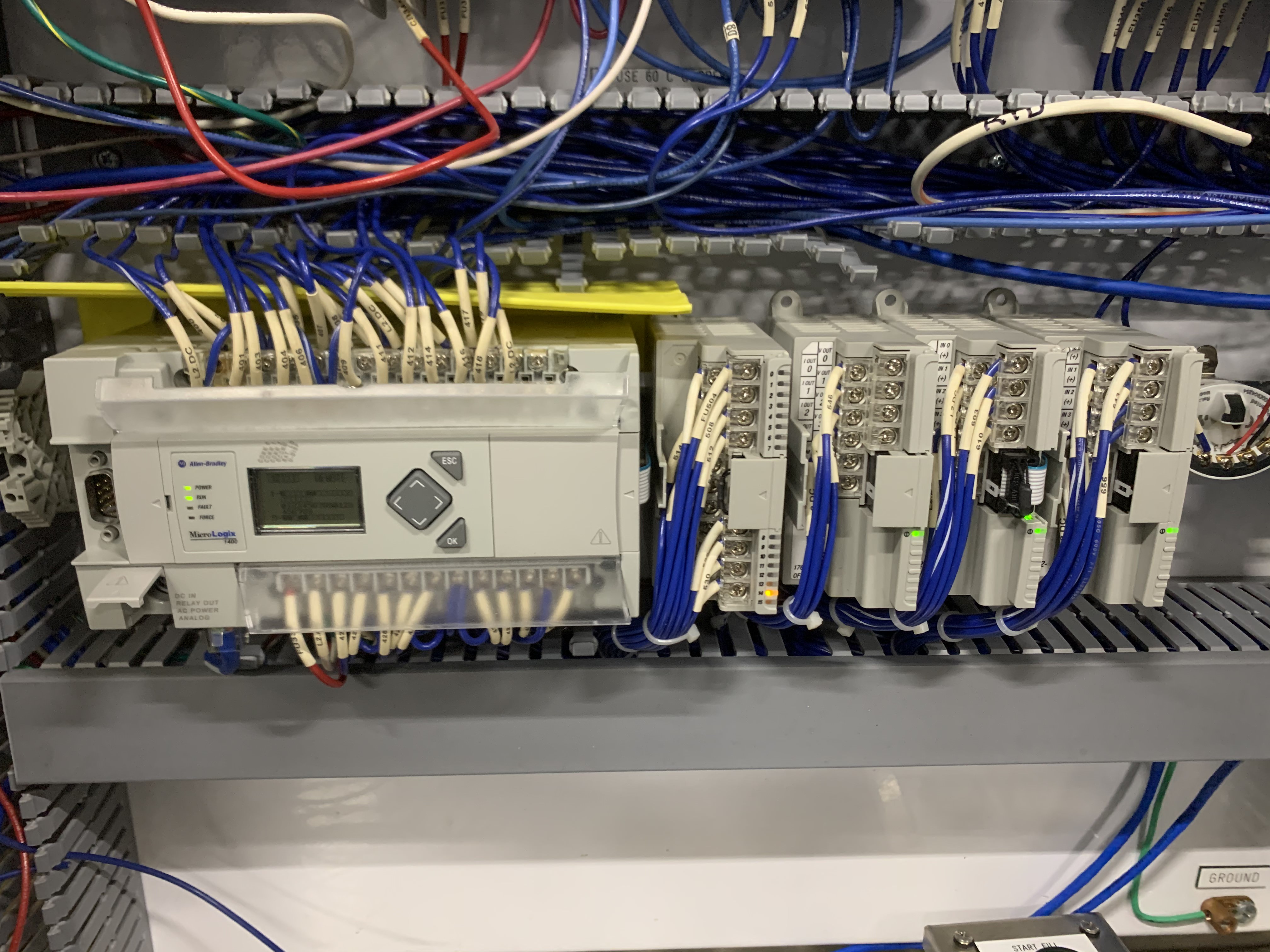

PLC/HMI Programming

- Free consultation

- PLC/HMI design, programming and troubleshooting

- Control panel design

- Systems integration

- Emergency services

- Remote troubleshooting

- Legacy system maintenance/troubleshooting

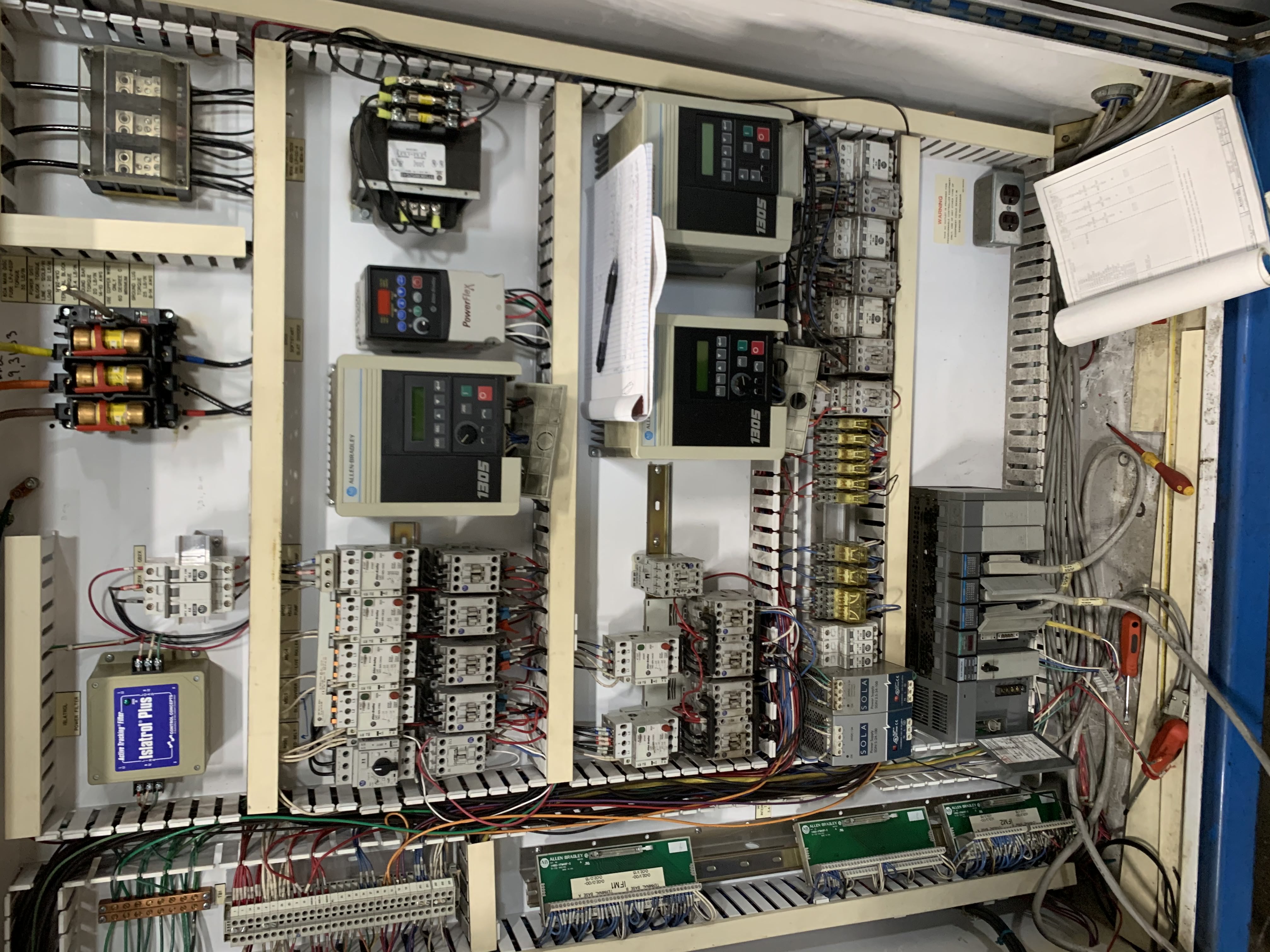

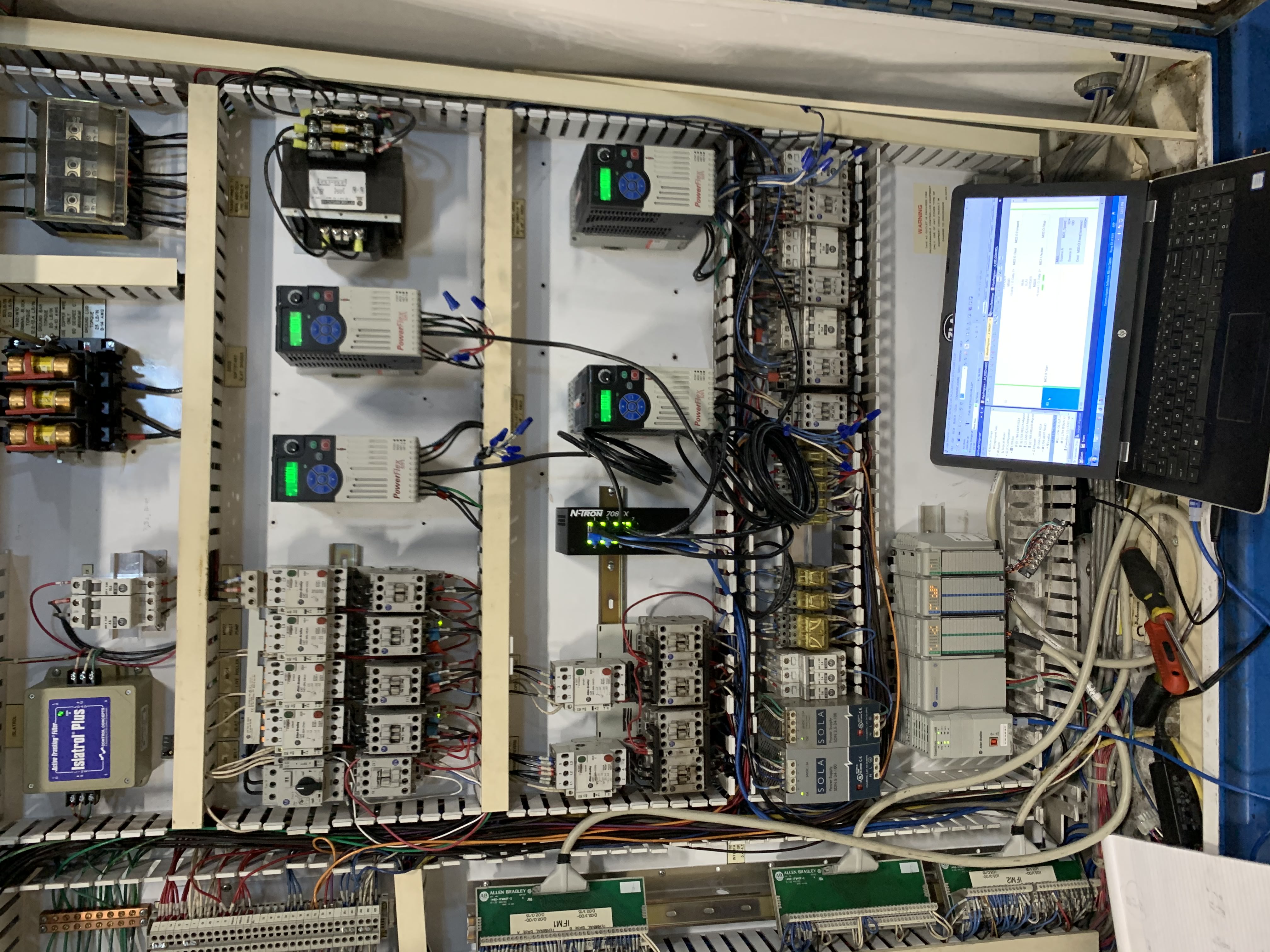

Electrical Controls

PLC's are the heart of any automated control system. But what about the electrical wires that tie everything together? Our exerienced controls electricians are available to troubleshoot, repair, add to, or upgrade your entire electrical control system.

Troubleshooting

At CSS, we know there are going to be times when you need us after hours. It's not your fault, and we will never punish you for calling us for help by charging an additional fee or overtime rates. We are your partner and we promise you will only ever pay our standard hourly rate for after hours services.